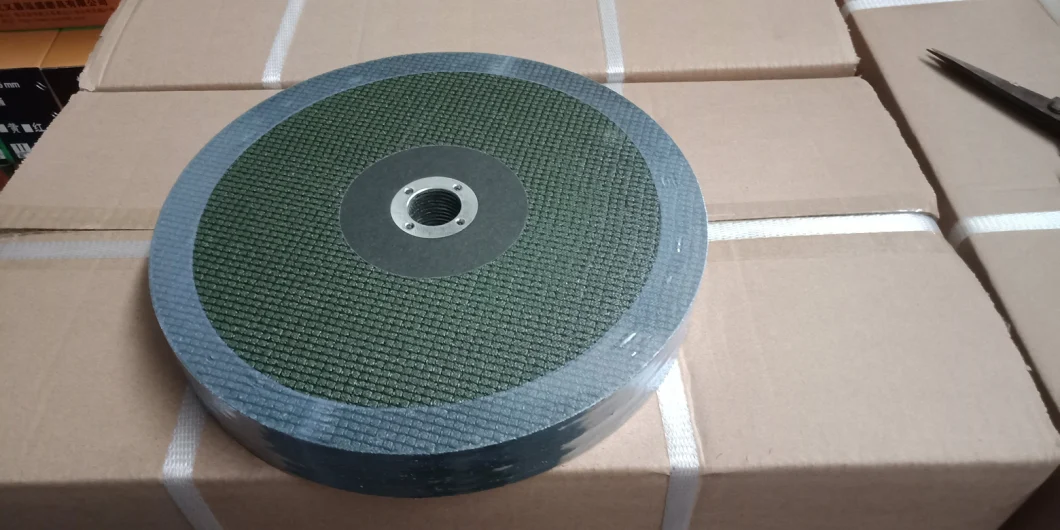

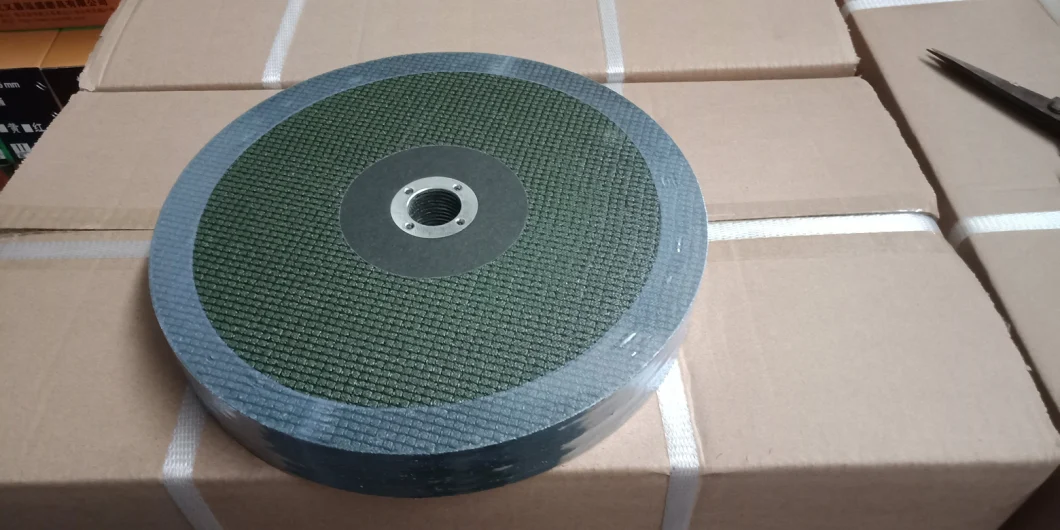

Product Specification

| Item Code | Type | Dimension | Dimension | Speed | Speed |

| (mm) | (Inch) | (R.P.M) | M/S | ||

| DAG1004016 | T27 | 100x4.0x16.0 | 4x5/32x5/8 | 15200 | 80 |

| DAG1006016 | 100x6.0x16.0 | 4x1/4x5/8 | 15200 | 80 | |

| DAG1154022 | 115x4.0x22.2 | 4.5x5/32x7/8 | 13300 | 80 | |

| DAG1156022 | 115x6.0x22.2 | 4.5x1/4x7/8 | 13300 | 80 | |

| DAG1254022 | 125x4.0x22.2 | 5x5/32x7/8 | 12200 | 80 | |

| DAG1256022 | 125x6.0x22.2 | 5x1/4x7/8 | 12200 | 80 | |

| DAG1504022 | 150x4.0x22.2 | 6x5/32x7/8 | 10200 | 80 | |

| DAG1506022 | 150x6.0x22.2 | 6x1/4x7/8 | 10200 | 80 | |

| DAG1804022 | 180x4.0x22.2 | 7x5/32x7/8 | 8600 | 80 | |

| DAG1806022 | 180x6.0x22.2 | 7x1/4x7/8 | 8600 | 80 | |

| DAG1808022 | 230x6.0x22.2 | 9x1/4x7/8 | 6600 | 80 | |

| DAG2306522 | 230x8.0x22.2 | 9x5/16x7/8 | 6600 | 80 |

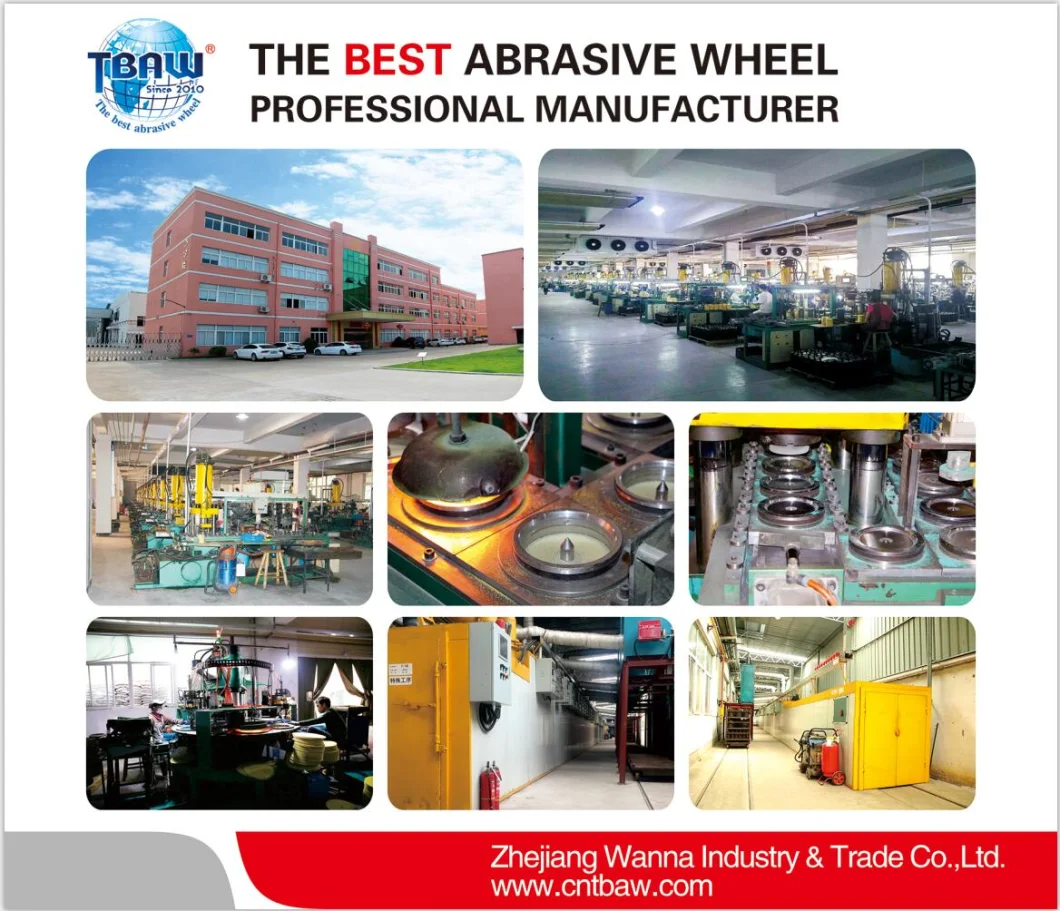

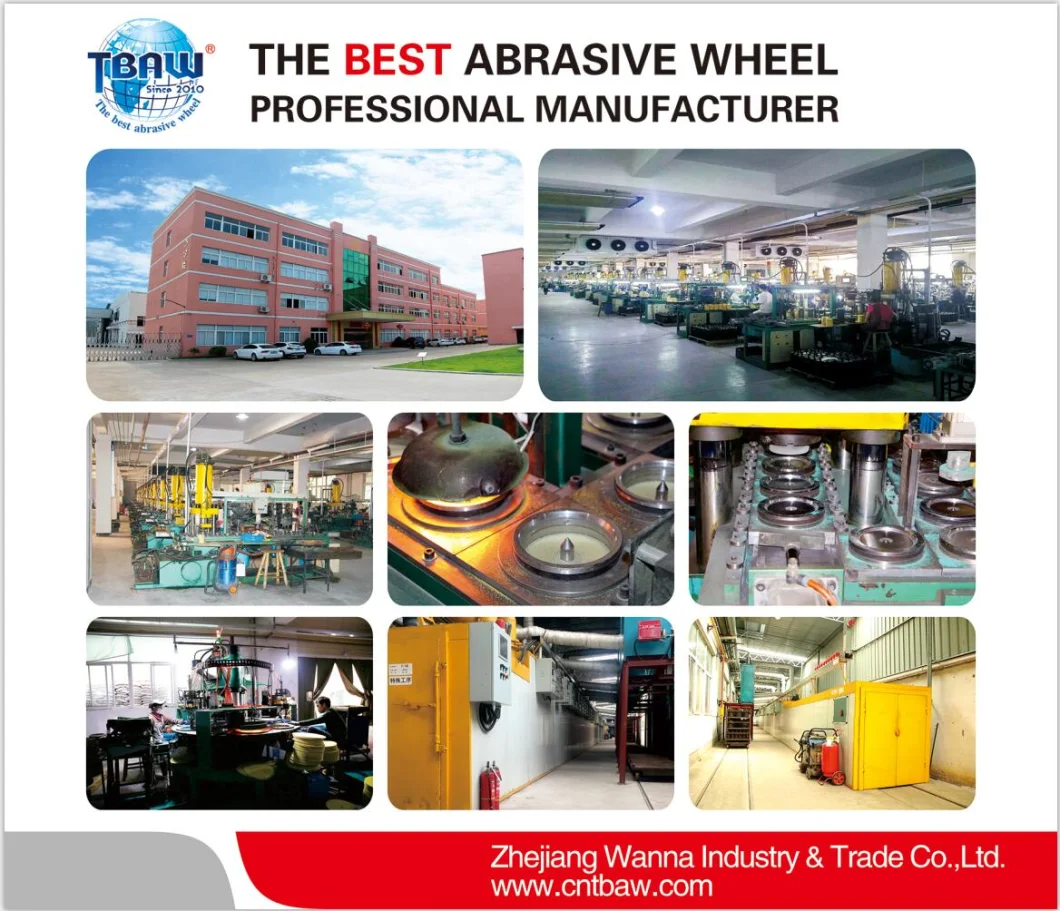

About Us

Zhejiang Wanna Industry & Trade Co., Ltd (TBAW) was established in 1995, located in Wuyi County, Zhejiang Province. As one of the leading abrasive manufacturers in China, TBAW specialized in manufacturing cutting and grinding wheels and always insists on Market-oriented and quality first.

Since 1995, TBAW has grown to become a professional manufacturer:

1. Around 25 years of experience in producing cutting and grinding wheel

2. Annual capacity up to 100million pcs and annual value more than 20million dollars.

3. Advanced equipment and technology: constant temperature in workshop and tunnel kiln controlled by the computer system

4. Inspection in each process during production

5. The management and quality control system in compliance with ISO9001.

The product has been certified by MPA.

6. Provide OEM to customers all over the world, including Europe, Latin America, Southeast Asia, etc.

Since 1995, TBAW has grown to become a professional manufacturer:

1. Around 25 years of experience in producing cutting and grinding wheel

2. Annual capacity up to 100million pcs and annual value more than 20million dollars.

3. Advanced equipment and technology: constant temperature in workshop and tunnel kiln controlled by the computer system

4. Inspection in each process during production

5. The management and quality control system in compliance with ISO9001.

The product has been certified by MPA.

6. Provide OEM to customers all over the world, including Europe, Latin America, Southeast Asia, etc.

Application

Package Details

1. Shrink package first

2. Inner brown box/colour box or plastic box/ metal box for 4"~5" discs;

3. Stardard export brown carton or color box.

4.Shipping by sea from Ningbo/Shanghai port or delivery to buyer request warehouse in China.

Standard carton and color carton with the plastic box inside is as below:

2. Inner brown box/colour box or plastic box/ metal box for 4"~5" discs;

3. Stardard export brown carton or color box.

4.Shipping by sea from Ningbo/Shanghai port or delivery to buyer request warehouse in China.

Standard carton and color carton with the plastic box inside is as below:

FAQ

Q1: Are you a trading company or manufacturer?

A1: We are manufacturer of cutting & grinding wheel over 20 years, located in Wuyi zhejiang.

Q2: What's your application for cutting & grinding discs?

A2: Used for metal, stainless steel, carbon steel, cast iron, stone, and so on.

Q3: What package do you use? accept OEM order?

A3: We usually packing as shrink + neutral inner box + standard export carton, we also accept OEM order, label, and package as customers' requirements.

Q4: What's kind of certifications you have?

A4: Yes, we have ISO 9001, MPa EN12413.

Q5: What's your daily output?

A5: 350000 PCS per day for daily products output for small inch, 35000pcs per day for big size like 14" and 16".

Q6: Do you have an inspection procedure before shipping?

A6: Yes, we do, 100% QC inspection Before Shipment.

Q7: Can you provide free samples?

A7: Yes, we can provide free samples, but samples freight belongs to clients.

Q8. What is your payment term?

A8: Usually TT 30% deposit, and balance against copy of B/L or L/C at sight,

Q9: How long is the delivery time?

A9: Around 30 days for container order. Around one or two weeks for sample order.