The main purpose:

This grinder is popular in homes, commercial use.

Application

Various grains: sesame, walnut, rice, black rice, soy, mung bean, peanut,lotus seed, corn, broomcorn, barley, buckwheat, oat, etc.

Various dry herbs: almond, poria cocos, red dates, semen euryales, Lycium barbarum, Coix seed, hawthorn, Chinese yam, fleece-flower root,red bean, frankincense, semen cuscutae, Angelica sinensis, Codonopsis pilosula, Astragalus membranaceus, etc.

Suitable for market, store, pharmaceutical processing plant, hospital, clinics, etc.

working principle:

This machine use activities and the tooth plate relative motion between the fixed tooth plate, the material through the tooth plate impact, friction, shear, impact each other and get crushed material.

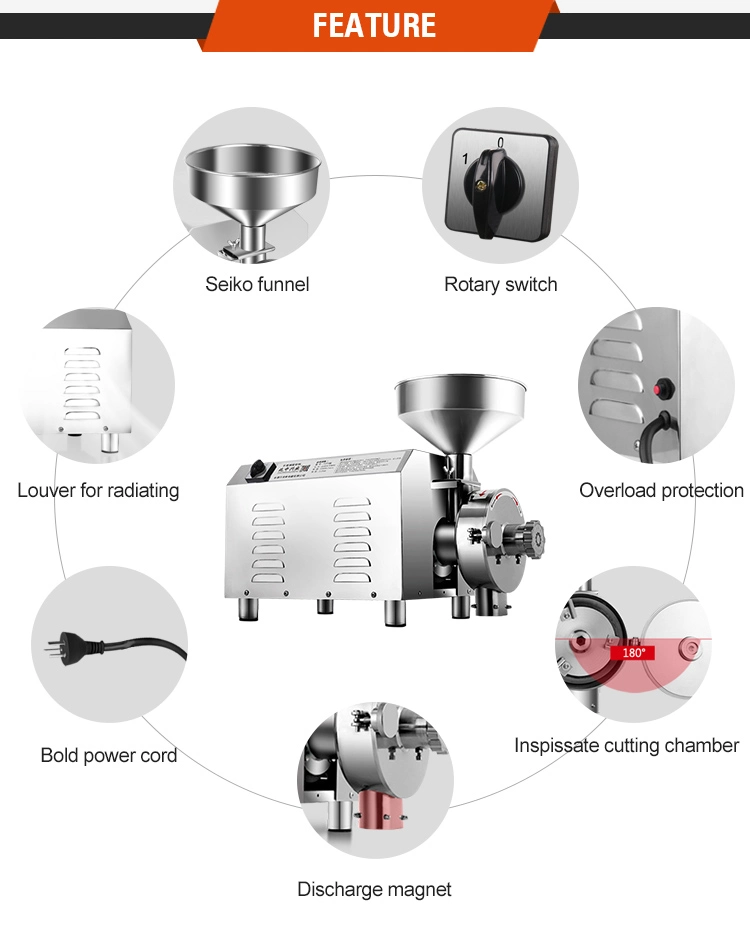

The machine features:

1) There is little noise, and the machine is stable when it works.

2) With overload protection reminding to ensure your safety

3)The machine can grind all kinds of food and medicines into 20~200 meshes.

4)Simple operation,non dust and fine powder.

5)No screen,and the thickness can be adjusted.

6)Stainless steel ,structure is simple, low energy, easy to clean, is the ideal grinding equipment.

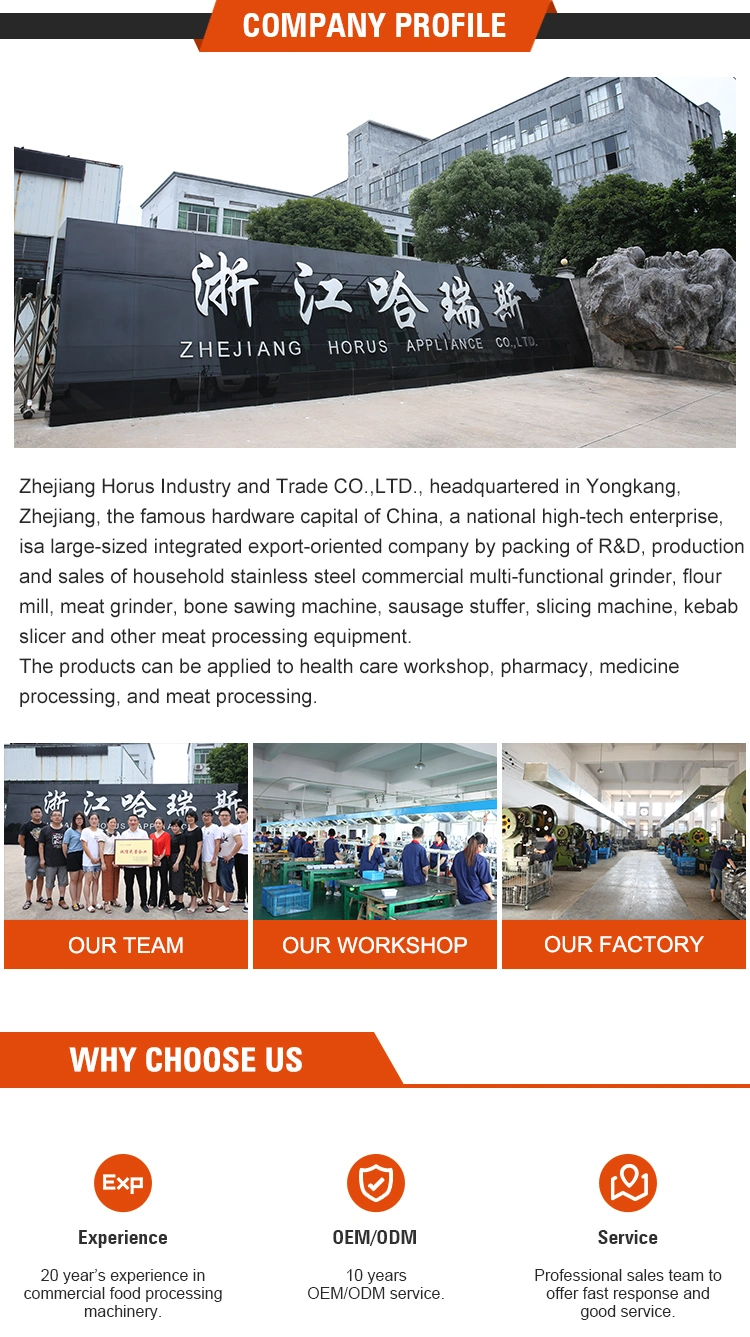

Flour Mill Machine

Instruction Manual

Instruction Manual

Thanks for your use(using) our product-multi-function flour milling machine!

Please carefully read the instruction manual before use the machine.

A,Technical parameter

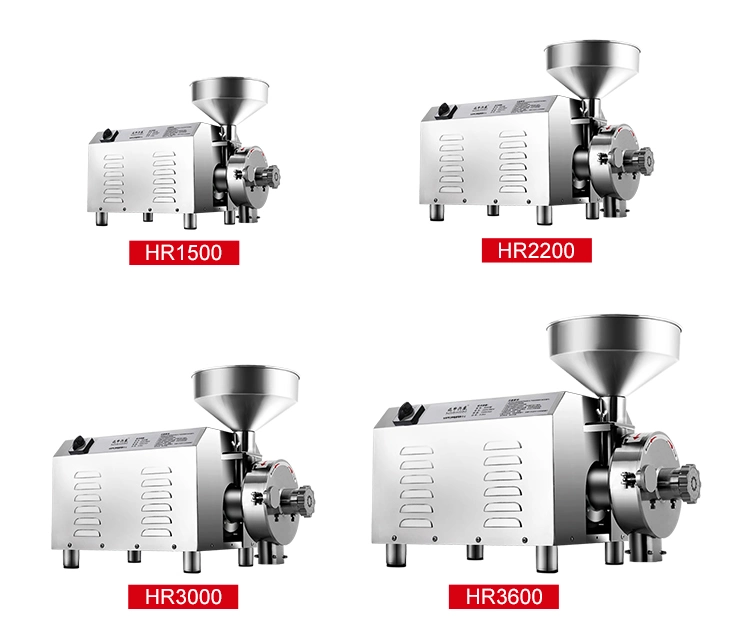

| Model | Voltage | Power | N.W. | G.W. | Size |

| 1500 | 110V/60Hz 220V~240V/50Hz380V/50Hz | 1500W | 41KG | 44.5KGS | 71.5X34.5X35CM |

| 2200 | 110V/60Hz 220V~240V/50Hz 380V/50Hz | 2200W | 43KG | 46.5KGS | 71.5X34.5X35CM |

| 3000 | 110V/60Hz 220V~240V/50Hz 380V/50Hz | 3000W | 51KG | 55.5KGS | 71.5X38X38CM |

| 3600 | 110V/60Hz 220V~240V/50Hz 380V/50Hz | 3600W | 55KG | 60KGS | 71.5X38X41CM |

B,Operation and Adjustment

1. Please open the front cover, fitted the abrasive disc, spring, apical axis,

bearing ect.

2. Pls insert the hopper into the feed inlet. Pls don't put much material into

the hopper.every time when the machine are crushing. Avoid to feed too

fast and motor stuck.

3.Order to prevent static abrasive disc rotation loose, please fix it into the

milling cavity.

4. Please put dry stuff into hopper, don't put wet stuff.into hopper, otherwise the abrasive disc will be stuck. Then the powder can't come out.

5. Abrasive disc work time must be adjusted according to powder finess require.

Adjust it to loosen the adjustment nut, powder finess by adjusting screw to adjust. Please tighten nut after adjusting.

6. Adjust dynamic abrasive disc: remove dynamic abrasive disc firstly,

then loosen the screw of abrasive disc. And taken down spring,

then fixed dynamic abrasive disc, adjustment abrasive disc until two abrasive

superposition.

C,Special Safety Rules

1.Please check screw of abrasive disc and feed hopper if it is ok before using the

machine every time.

2.Please clean and dry inside machine after using every time.

3.Please repair or replace the part when the machine parts damaged or abrasion.

4.Do not put the machine inversion please put it horizontal and cut off power.

5.The machine should be installed horizontal on the work table.

6.Please wait a moment to put the material into the machine after turn on

the power. Don't put much material in the machine to avoid much material and motor stuck.

7.Please remove the material from machine when complete the process and

cut off the power suddenly.

8.All material must be dry. And don't left metal or stone and other stuff in hopper.

| Crusher room stick or there are metal stuck in it | There are some metals or stuff in machine, then machine part are damaged. | Cut off power and check hard goods or change part. . |

| Grinding is not fine | two abrasive disc is not same level abrasive disc is coloboma or breaken | Adjustment two abrasive disc are same level. Change abrasive. |

| Low efficiency | Abrasive disc is not sharp Feeding difficultly | Change abrasive Adjustment the space between of abrasive The material size is too big please crush them suitable size. |

| Motor can't work | Feeding too much Voltage too low Abrasive disc get stick | Reduce feeding. Don't use the machine when the power is not normal. Adjustment the space of abrasive disc and clean up abrasive disc. Replace abrasive disc. |

| Packing List | |

| Mill Flour Machine | 1 pc |

| Hopper | 1 pc |

| Abrasive disc | 4 pcs |

| overload switch | 1 pc |

| Brush | 1 pc |

| Instruction Manual | 1 pc |

1,Motor Cover

2.Motor

3.Motor Mounting Flange

4.Motor Bottom

5.Hopper

6 Rubber Cushion

2.Motor

3.Motor Mounting Flange

4.Motor Bottom

5.Hopper

6 Rubber Cushion

7.Cushion of abrasive disc

8. static abrasive disc

9.Crushing Cavity

10.Adjustment Screw

11.Adjustment Nut

12.Top Axis

13.Bearing

14.Front Cover

15. dynamic abrasive disc

16. Grinding Sleeve

17.Adjustment sheet

18.Spring

E,General breakdown and operation method8. static abrasive disc

9.Crushing Cavity

10.Adjustment Screw

11.Adjustment Nut

12.Top Axis

13.Bearing

14.Front Cover

15. dynamic abrasive disc

16. Grinding Sleeve

17.Adjustment sheet

18.Spring

| Breakdown phenomenon | Breakdown reason | Correct method |

| Motor can not start up or startup difficultly | Check whether the overload switch is damaged, The wire diameter is too small voltage is below level Capacitor is damage . | replace overload switch replace suitable wire, when voltage is stable to re-start |

| Motor weakness The temperature is too high | Motor cutting-out motor bearing damage motor work long time | Check motor Replace motor bearing According to standard time work or pause. |

| Machine body is strong quakely | Other part weight not equilibrium The coupling is bending deformation Bearing damaged dynamic abrasive disc not equilibrium | Check the part and adjustment weight equilibrium Replace coupling Replace bearing Adjustment dynamic abrasive disc equilibrium |